Please click the contact button below that will take you to our contact us page, and fill out the information form. If you would like to inquire about additional capabilities please be sure to note your specific requirements in the “Comments” field or call so one of our engineers can assist you directly.

OUR WORK QUALITY

Loftis manufacturing is committed to manufacturing the highest quality tooling for our customers. We follow the most stringent quality standards and utilize advanced equipment and technologies to verify the accuracy and quality of each tool and subsequent parts. Our goal is to manufacture precision tooling that meets or exceeds out customers’ expectations.

All parts are inspected by CMM procedures to ensure accuracy and repeatability to meet customer standards and GD&T requirements. Production parts are routinely checked for accuracy. Reverse engineering is also available through the use of CMM/Laser Scanner capacities.

DESIGN APPROVAL

DESIGN APPROVAL

MANUFACTURING STANDARDS

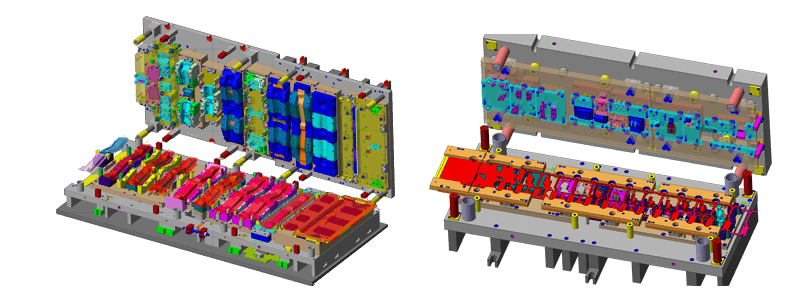

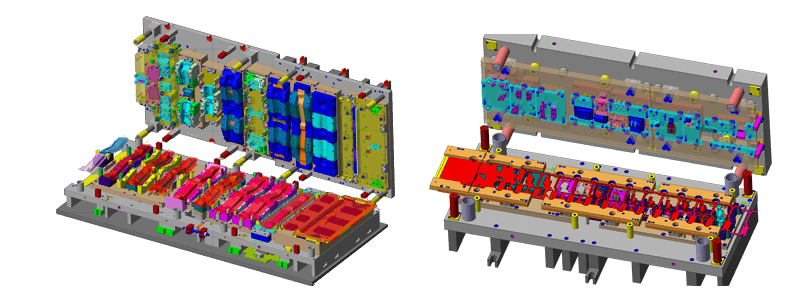

Our experienced die makers utilize the latest technology and state-of-the-art equipment to manufacture the tool. We have the capacity to manufacture intricate tooling to your requirements. Loftis Manufacturing specializes in manufacturing progressive and line tooling.

MANUFACTURING STANDARDS

Our experienced die makers utilize the latest technology and state-of-the-art equipment to manufacture the tool. We have the capacity to manufacture intricate tooling to your requirements. Loftis Manufacturing specializes in manufacturing progressive and line tooling.

QUALITY ASSURANCE

Loftis Manufacturing employs the most advanced measuring systems and inspect all parts to ensure that they meet our clients design specifications and application requirements.