PRODUCTS & SERVICES

Loftis Manufacturing, Inc. is a Tool and Die Design & Build Corporation contracted to produce Progressive, Line, Electrical Terminal, Transfer, Four-slide and Compound dies. We offer design and build services for a broad range of manufacturing industries, with tool build capacities of 50-1250 Tons. We have the capability to provide our customers with integrated service from die concept development through design, build and tryout for their dies. We strive to continuously improve our processes and stay ahead of the latest technology, allowing us to streamline our production and ultimately save our clients time and money. Loftis Manufacturing is happy to provide our customers with the following services:

DESIGN & ENGINEERING

Our experienced engineering staff has the technical knowledge to produce precise, efficient designs for Progressive, Line, Electrical Terminal, Transfer, Four-slide and Compound dies. All of the designs are 100% detailed and engineered in full 3D using the latest Vero VISI software. VISI is acknowledged as one of the world’s leading PC based CAD CAM software solutions for the Tool & Die industry. It offers a unique combination of applications, fully integrated wireframe, surface and solid modelling, comprehensive 2D, 3D and 5 axis machining strategies with dedicated high speed routines. Vero Software offers dedicated solutions that eliminate the links between varying software suppliers and the solid-to-surface or CAD / CAM geometry conversions required by traditional systems, saving our customers time. Utilizing this state of the art software allows Loftis Manufacturing to offer many time-saving, and ultimately money saving benefits to our customers. Additionally, we also offer formability simulations upon request.

DESIGN & ENGINEERING

TOOL & DIE ASSEMBLY & TRYOUT

Loftis Manufacturing provides assembly and tryout for Progressive, Line, Electrical Terminal, Transfer, Four-slide and Compound Dies with press capacities from 50 – 1250 tons. Our team of highly-skilled journeyman tool & die makers take great care to insure that all dies are built to the highest quality. The dies are then quality-checked against the design to verify that they meet the design requirements. Ensuring that you receive quality tooling that is built accurately and will provide years of profitable production for your company.

TOOL & DIE ASSEMBLY & TRYOUT

Loftis Manufacturing provides assembly and tryout for Progressive, Line, Electrical Terminal, Transfer, Four-slide and Compound Dies with press capacities from 50 – 1250 tons. Our team of highly-skilled journeyman tool & die makers take great care to insure that all dies are built to the highest quality. The dies are then quality-checked against the design to verify that they meet the design requirements. Ensuring that you receive quality tooling that is built accurately and will provide years of profitable production for your company.

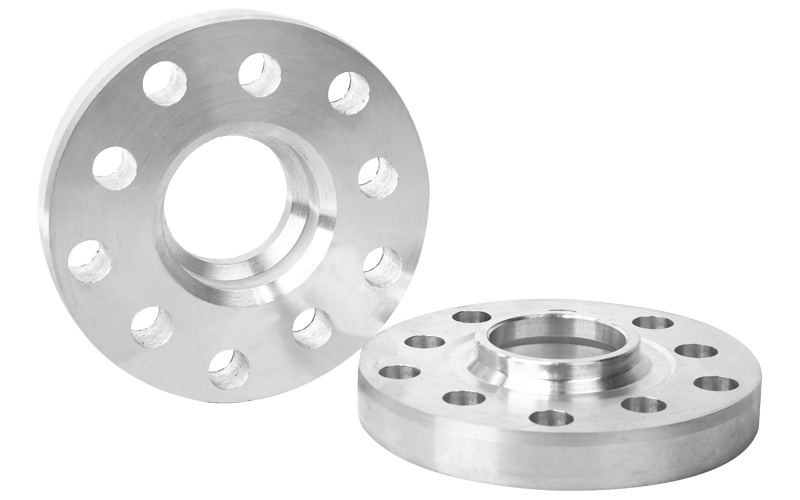

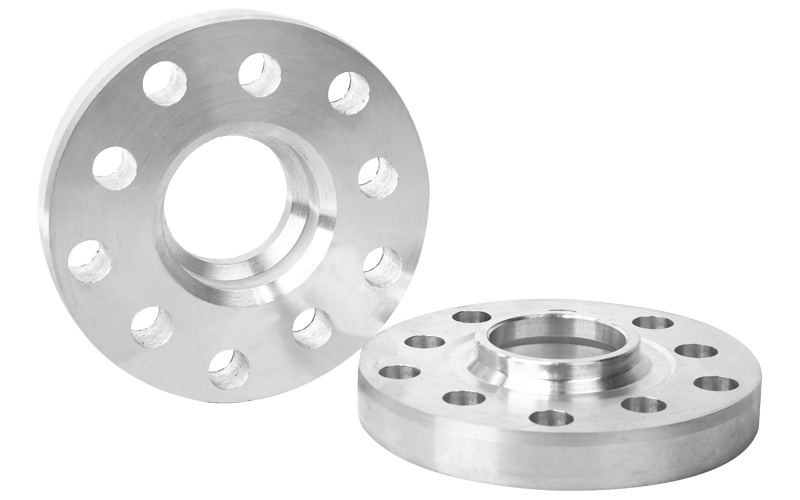

MANUFACTURING & MACHINING

We are committed to manufacturing the highest quality products. We offer quality detailing fabrication as well as small to mid-size metal stampings at competitive pricing. Loftis uses various production methods, including progressive die stamping, four-slide, and deep drawing to make sheet metal parts. We have the capability to fabricate material include steel, stainless steel, aluminum, brass, and copper ranging in thickness from 0.010 to 0.246 inches. Our manufacturing methods are fast and dependable, producing parts that deliver great part performance.

In addition to our other services we also offer CNC programming & machining services.

MANUFACTURING & MACHINING

We are committed to manufacturing the highest quality products. We offer quality detailing fabrication as well as small to mid-size metal stampings at competitive pricing. Loftis uses various production methods, including progressive die stamping, four-slide, and deep drawing to make sheet metal parts. We have the capability to fabricate material include steel, stainless steel, aluminum, brass, and copper ranging in thickness from 0.010 to 0.246 inches. Our manufacturing methods are fast and dependable, producing parts that deliver great part performance.

In addition to our other services we also offer CNC programming & machining services.

REQUEST A QUOTE

Please click the contact button below that will take you to our contact us page, and fill out the information form. If you would like to inquire about additional capabilities please be sure to note your specific requirements in the “Comments” field or call so one of our engineers can assist you directly.